product list

hot products

Latest News

Guangzhou, Oct 23rd-27th, 2025 – Quanzhou Xingyuan Supply Chain Management Co., Ltd., a leading integrated hygiene products supplier, is showcasing its one-stop manufacturing and supply chai...

As the National Day of the People's Republic of China approaches, Fujian Xingyuan Co., Ltd. would like to extend its warmest greetings to our valued international customers and partners. We ...

About the Nanjing Exhibition information: FuJian XingYuan Industry Co.,Ltd focus on produce diaper,sanitary napkin and underpads raw materials,machine many years. Such as nonwoven,PE film,fr...

2017-03-01

As we know, SAP (super absorbent polymer) as "engine" of diapers , largely determines the merits of diaper performance. There are several indicators to measure SAP performance: retention ratio of water absorption,rate of absorption, absorption amount of pressure, liquid permeability, particle size.

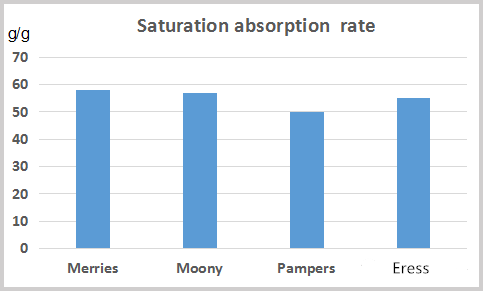

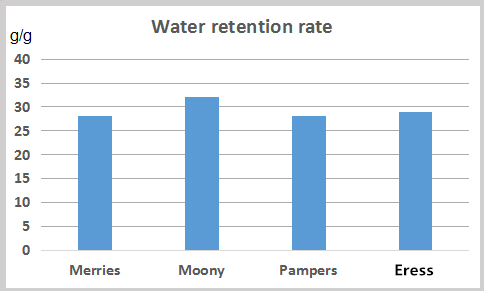

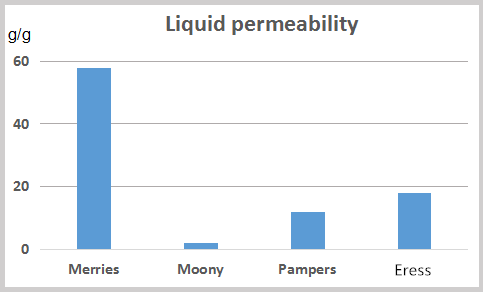

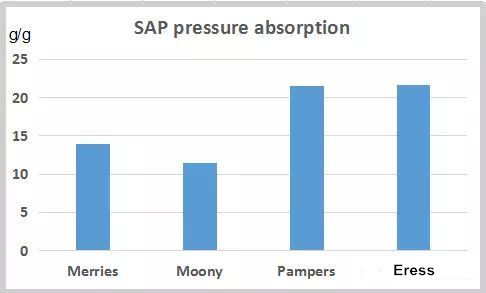

We chose the Japanese Merries, Moony, American Pampers, Germany Eress. These four brands passed the standard test method, the performance is better by Merries, Eress, Pampers, Moony. We use the professional technology to separate the absorbent polymers from the diapers, then tested the saturation absorption and water retention rate under 0.9% physiological saline, the test results are as follows:

Many people considered as the SAP's water absorption rate is more higher more better, but they don’t know that it’s a complicated relationship among these indexes of the SAP, it’s appears like complementary and interacting relationship. Such as the water retention and absorption rate with the liquid permeability. Generally speaking, if the water retention and absorption rate of SAP is high , the liquid permeability will be either normal or sometimes even worse; On the contrary, if the liquid permeability is better, the water retention and absorption rate will not be too high.

Therefore, a large number of experimental data show that the superior performance of diapers is not only determined by the high absorbency SAP, but keeping about 30 water retention capacity, in the meanwhile increase the liquid permeability and SAP pressure absorption. In order to ensure that urine conduct quickly in SAP and lock the moisture in the urine.

previous article :

About Nonwovensnext article :

Use And Maintenance Of Hot Melt Adhesive Machine System fjxingyuan

fjxingyuan

Linda@fjxingyuangroup.com

Linda@fjxingyuangroup.com

360391852

360391852

+86-595-85922600

+86-595-85922600

+86-13514004600

+86-13514004600

Scan our WeChat

Scan our WeChat