product list

hot products

Latest News

Guangzhou, Oct 23rd-27th, 2025 – Quanzhou Xingyuan Supply Chain Management Co., Ltd., a leading integrated hygiene products supplier, is showcasing its one-stop manufacturing and supply chai...

As the National Day of the People's Republic of China approaches, Fujian Xingyuan Co., Ltd. would like to extend its warmest greetings to our valued international customers and partners. We ...

About the Nanjing Exhibition information: FuJian XingYuan Industry Co.,Ltd focus on produce diaper,sanitary napkin and underpads raw materials,machine many years. Such as nonwoven,PE film,fr...

2017-02-01

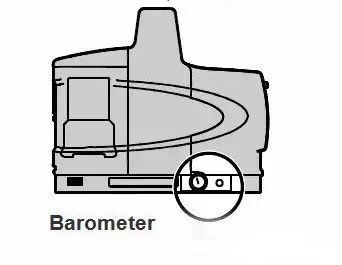

4. The supply air pressure of the machine system shall not be less than 5 Bar, and the air supply shall be dust-free, oil-free and clean.Gun solenoids pressure monitoring is recommended to install a separate table,the instantaneous value of the fluctuations in air pressure should not exceed 1.5Bar.

5. Pump pressure recommended setting as 2-4 Bar.

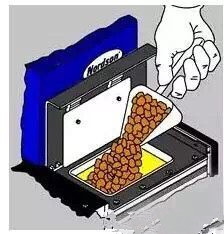

6. To develop a good habit of adding glue, adding the glue with a small quantities and several times. Regularly check the glue level in the glue box and keep the glue level in the same height.

7. The liquid level is usually maintained at the glue cylinder 2/3 level above, not less than 1/2 of the cylinder (for special case, such as a small amount of glue can be lower than the cylinder 1/2 and follow the principle of adding the glue with a small quantities and several times).

8. Keep the glue box clean, adding the impurities into the glue cylinder is strictly forbidden, cover the glue box immediately after adding the glues. Seal the bags contained the hot-melt adhesives in time to keep away from the dust and other impurities.

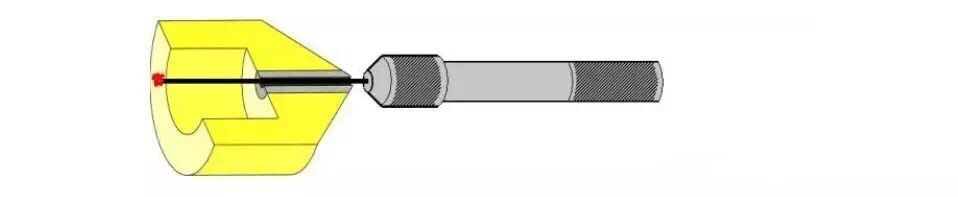

9. After the nozzle is blocked, it must be cleaned up in time to ensure that the spray pressure and flow are normal.

10.When adjusting the 90 ° nozzle spray glue position, nut must be released and rotary spray nozzle hole position, and then tighten out nut after adjusting nozzle spray glue position.

11. Solenoid valve should be installed near the gun, it is recommended to use a metal pipe directly attached to the gun body to ensure a good response of spray gun and improve the accuracy of the location of the spray.

12. Replace the different brands and traits of hot-melt adhesives, the hot melt glue in the original rubber cylinder must be used up or emptied before adding new glue. To avoid the two kinds of hot melt adhesive mixed in the cylinder flotation of gels and impurities, aggravate the hot melt adhesive deterioration of carbonation and then plug the nozzle, filters and so on.

Maintenance of hot melt machine system

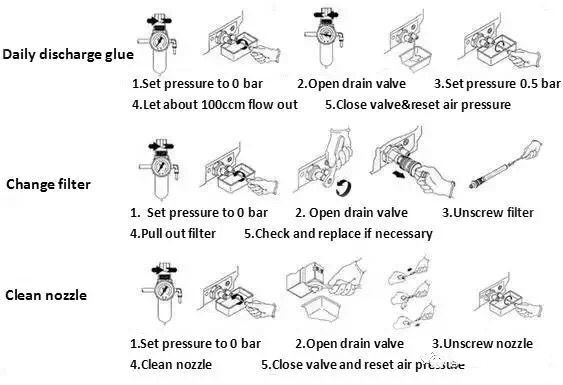

1. Clean the melted and cover the surface of the gun carbides every day, so as not to affect the normal work of the gun. If the surface of the gun has been formed carbide, you can use R solvent wipe softened to remove.

2. Spray the melted filter every day.

3. Check and clean the filter of hot melt filter machine every month.

4. Every six months should replace filter core between the throat of pipe and glue gun. Check whether there is any damage or abnormality in the electrical connection inside the hot melt adhesive main unit. Make sure all electrical connections are locked.

5. Clean the hot melt machine system thoroughly every year and replace the melted filter.

previous article :

Water retention for SAP of International brand diapersnext article :

The Application of Position Glue in Sanitary Napkins fjxingyuan

fjxingyuan

Linda@fjxingyuangroup.com

Linda@fjxingyuangroup.com

360391852

360391852

+86-595-85922600

+86-595-85922600

+86-13514004600

+86-13514004600

Scan our WeChat

Scan our WeChat